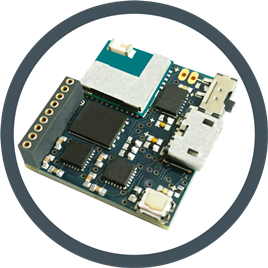

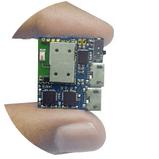

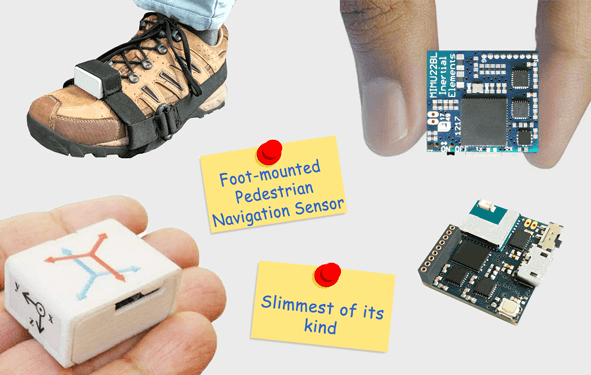

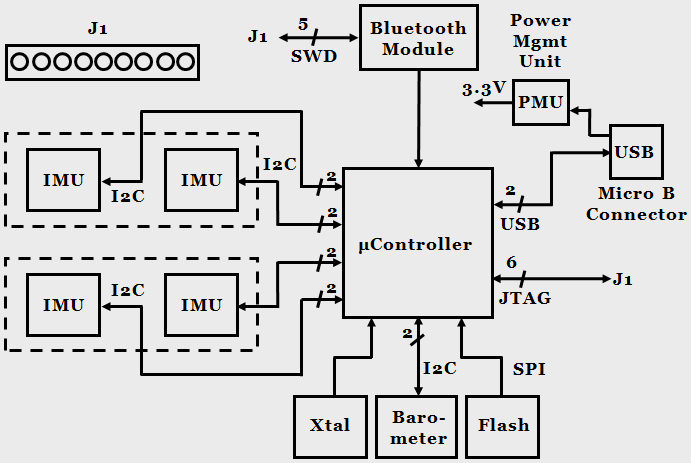

An IMU-array based Precision Wearable Motion Sensor Platform (IMU) - The Osmium MIMU22BL - is a miniaturized motion sensing multi-IMU (MIMU) platform, configured as shoe-based Pedestrian Dead Reckoning (PDR) sensor for real-time indoor localization in GPS denied environment. It is a smart IoT sensor node, capable of providing simplified yet information rich data, thereby relieving application platform and developers from the compute intensive development and tasks. This greatly simplifies data interface and makes integration of this device with rest of the localization system, effortless. Thus resultig in improved tracking accuracy, relaxes constraints on the integration platform and significantly reduces time-to-market.

Presence of on-board floating point processing capability, along with four IMUs array, makes sensor fusion and motion processing possible within the module itself, which in turn results in very accurate motion sensing. Being one of the thinnest IMU in the market, it is suitable for applications with space constraints, e.g. wearable motion sensing. It finds applications in indoor real-time location systems (RTLS) for industrial workers and first responders. It also has applications in robotics, urban geo-survey, AR, gaming, gait biomechanics, wearable IoT etc.

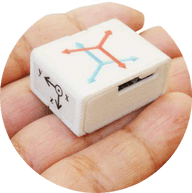

MIMU22BLP is the packaged version which includes encased assembly with 150 mAH Li-ion battery. MIMU22BLPX is also the packaged version, with 500 mAH Li-ion battery for day-long battery backup.

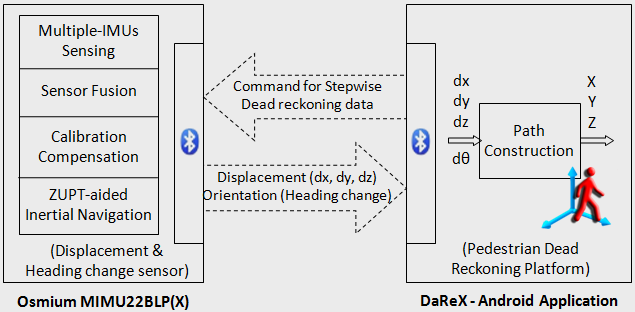

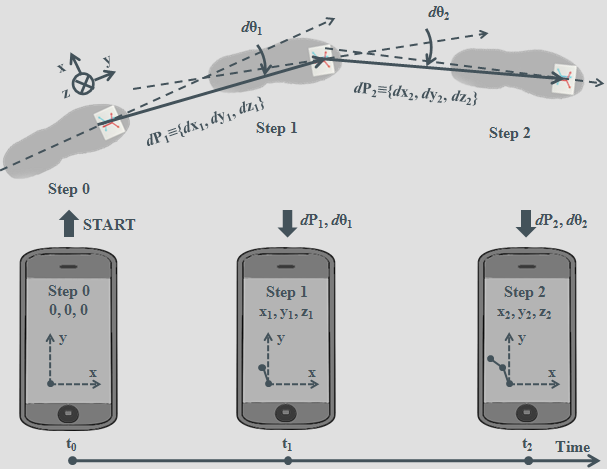

The PDR system consisting of the shoe-sensor (IMU), The Osmium MIMU22BLP / MIMU22BLPX, and the interfacing Android application DaReX. Data from on-board multiple IMUs are sampled, fused, calibration compensated and undergo navigational computation to produce displacement and heading information. The MIMU22BLP / MIMU22BLPX transmits requested data in response to an appropriate command from DaReX. DaReX constructs tracked path using stepwise PDR data from the shoe-sensor.

The IMU-array along with the motion-processing-inside approach not only improves accuracy, but also simplifies PDR data transmission. The PDR data, i.e. displacement and heading change, is transmitted at every step in a very simple format. Data transmission frequency matches with the step frequency which is typically 1 Hz for normal walk. Thus the low rate PDR data (typically few tens of bytes per second) reduces chances of transmission losses as well. The PDR data also removes computation burden from the application platform. The modular approach relaxes constraints on the integration platform, lets application engineer focus on incremental development and significantly reduces time-to-market. Please go through the short informative video under the title "Pedestrian Dead Reckoning with Foot Sensors" in Blog section."

Please visit Support section for resources, tutorials, FAQs etc and Blog for more information on technology.